blogs

blogs

The optimisation dilemma; techniques to discover the very best electric motor designs

In the world of optimisation, one of the most fundamental challenges is finding the right balance between exploration and incremental improvement. This dilemma appears in fields ranging from reinforcement learning to drug discovery, but it plays an especially critical role in engineering design where solution spaces are vast, complex, and often poorly understood.

At Monumo, we face this challenge head-on in our work, optimising electric motor designs. Our goal is to discover new and efficient motor configurations that outperform conventional designs on cost, efficiency and other KPIs. But as with any optimisation task, we must constantly decide: do we search broadly for novel solutions (exploration), or refine and improve the best candidates we already know (incremental improvement)?

Optimising motors: more than just tuning parameters

Designing an electric motor involves many variables: rotor geometry, magnet placement, stator winding patterns, material distributions, and more. The search space is multidimensional and nonlinear, filled with local optima that can easily trap naïve optimisation strategies. At Monumo, we use techniques like genetic algorithms (GAs) to navigate this space, inspired by biological evolution to explore, combine, and mutate potential solutions.

However, we’ve found that a key factor limiting exploration is not the optimisation algorithm itself, but the way we represent motor designs.

Parametrisation shapes the search space

When we speak of parametrisation, we mean how a motor design is mathematically encoded: which parameters are exposed, how geometry is constructed from those parameters and how flexible or constrained that encoding is. Traditional parametrisations often favour simplicity. But this approach suffers from being too rigid, effectively restricting the search space the optimiser can access. Even the best algorithm can only explore designs allowed by the parametrisation.

This realisation led us to a core insight: to truly enable exploration, we needed to rethink how we parameterise motor designs.

Parametrisations that favour exploration

At Monumo, we've developed a more expressive parametrisation. This expands the variety of motor geometries our optimisation tools can access, without impacting the validity of designs, or increasing the search space significantly. This new approach preserves physical realism and manufacturing constraints and allows the optimisation algorithm to more effectively modify the motor parameters without invalidating the designs.

By enabling broader exploration, our parametrisation unlocks higher diversity in generated motor candidates, which is essential for evolutionary algorithms like GAs to thrive. More diversity means a richer gene pool which prevents premature convergence to ensure the search doesn't get stuck in a local optima.

The payoff: better designs, found faster

In practice, we've observed that this improved design representation leads to a faster convergence toward optimal solutions. Our optimiser gains access to more performant configurations, and converges to optimal designs quicker. We're now able to reach solutions that were previously inaccessible - either because they weren't encoded at all, or because the optimiser couldn't find a path to them.

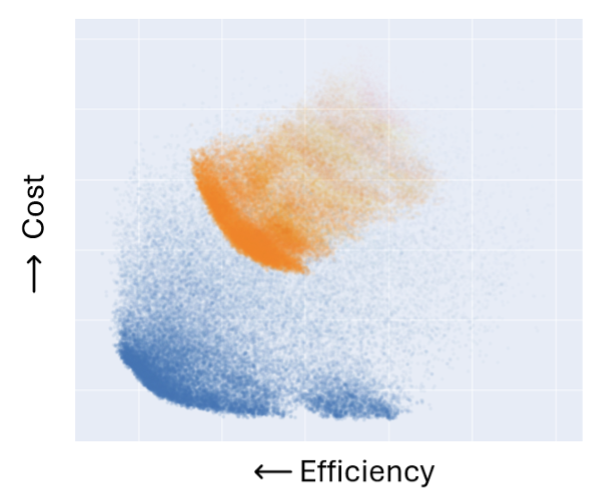

*Figure 1. Optimisation runs for old parametrisation (orange) and our new parametrisation (blue).

Figure 1. shows two multi-objective optimisation runs, where we want to reduce the total material (BOM) cost of the motor and at the same time increase its efficiency. The best designs (cost effective and efficient) are in the bottom left of the figure. Both runs have explored around 30k designs, but you can see that our new parametrisation (blue) covers much wider target space and ultimately converges to better designs – the blue pareto front is much further down-left than the orange one.

The animation above shows the overlay of designs that are being explored with our new parametrisation during the optimisation run. You can see a big initial variety of designs that converge to the optimal solution towards the end.

In summary, by rethinking how motor designs are parameterised, we've dramatically enhanced the exploratory power of our Anser optimisation engine. This shift allows for greater design diversity, avoids premature convergence, and accelerates discovery of superior motor configurations. All of these will benefit any optimisation approach; agnostic to whether it’s genetic algorithms, Bayesian optimisation or generative design. The result: better designs, achieved faster, and with far greater confidence that the best options in the space have actually been found.