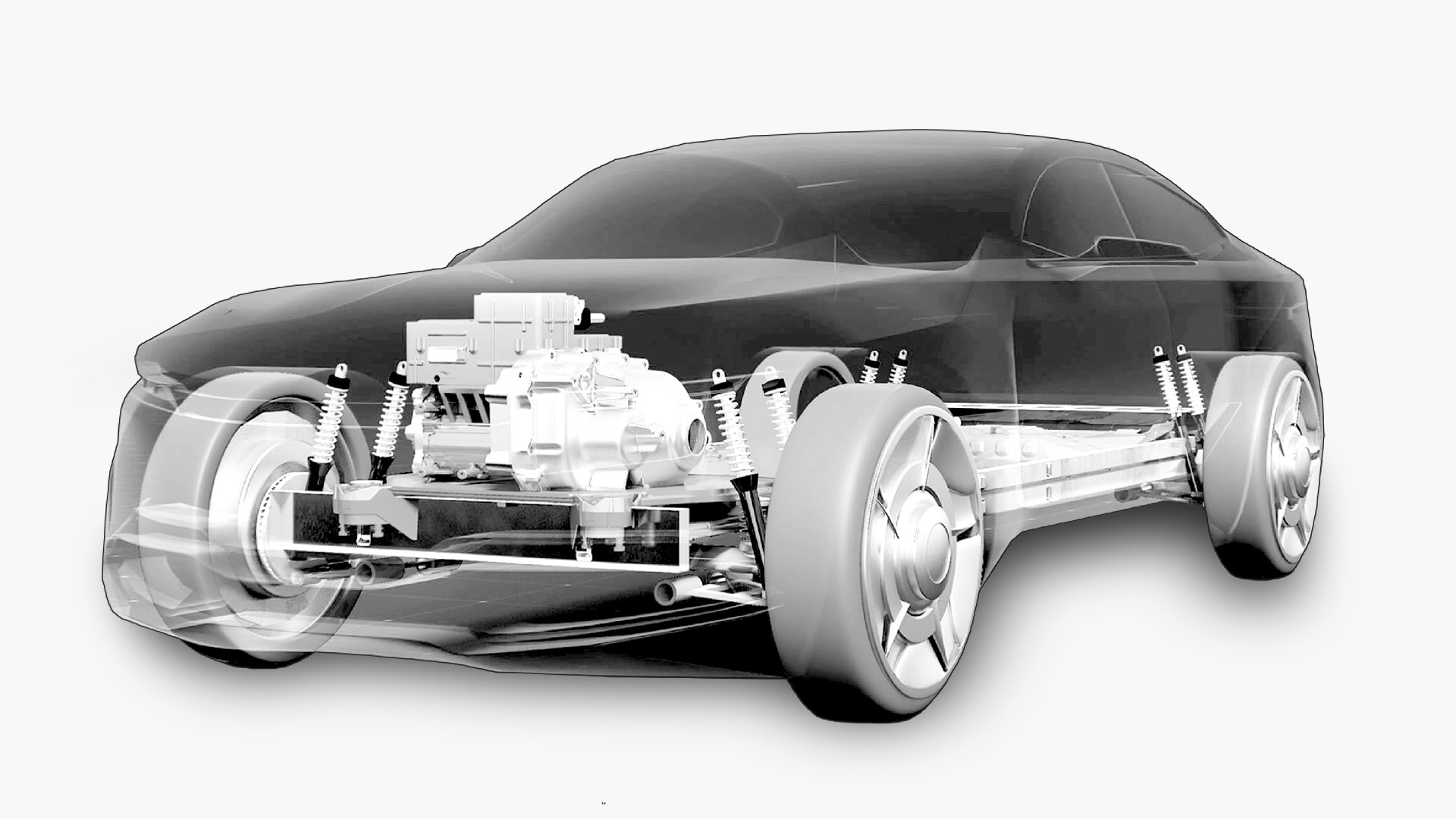

Our multi-physics deeptech engine Anser® has been built specifically to create the next generation of electric drives optimised within EV powertrain systems.

We partner with leading automotive companies to create and license motor system designs that give them a true competitive advantage.

Optimal solutions for new or existing designs

Anser finds improvements in your current motor or creates a brand-new electric drive unit to your specifications, ensuring the system is optimised for performance, reliability, and cost.

Cut costs, raise efficiency

Anser handles competing goals-performance, volume, efficiency, cost. Working with us, we empower your teams to quickly define and iterate requirements and attributes to allow Anser to create a class-leading EV design with optimal trade-offs.

System-level or single-component optimisation

While Anser can optimise your e-motor requirements alone to deliver optimal performance and flexibility for your EDU or platform, it can also co-optimise the motor, gearbox and inverter simultaneously, trading off design parameters to find hidden system optimisations.

Massive design exploration in days

Anser’s scalable architecture is unrivaled in exploring millions of design tradeoffs in just days, allowing you to iterate rapidly and uncover superior system designs in considerably shorter timescales than previously imagined.

Your expertise, our tech

No need for your top engineers to build AI/ML or multi-physics tools - Monumo provides the deeptech foundation with Anser. You stay innovative, focusing on your product DNA, while Anser powers your competitive advantage.

In case you were wondering

These are some of the most frequently asked questions.

If you have a specific question, please get in touch